MANUFACTURING CAPABILITIES

CAPABILITIES

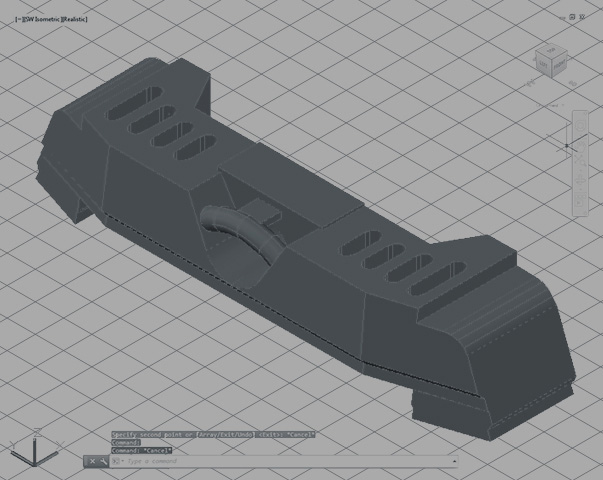

| Product range: | 2.5m × 4.0m × 2.5m in dimension, up to 11,000 kg in weight |

| Material Range: | see table |

| Process: | No bake (Alkaline phenol) |

FACILITIES

Design and Pattern Production: A gating and riser system design team operates CAD and simulation software to ensure castings contain defect-free

- Melting:

- • 3 mt induction furnace (2 units)

- • 0.5 mt induction furnace

- • 1 mt induction furnace

- Heat-treatment:

- (Quenching/Normalizing/Temping by LPG fired and equipped with automatic controlling and recording device)

- • 2.7m × 4.4m × 2.5m

- • 2.0m × 3.5m × 2.5m

- • 1.7m × 2.9m × 1.5m

- Machine shop:

- • Vertical Machining Lathe: 2 units

- • Horizontal Machining Lathe: 1 unit

- • Boring Machine: 1 unit

- • Milling Machine: 1 unit

- Quality Control:

- • Chemical testing

- • Sand testing (LOI, Compressive Strength)

- • Mechanical testing (Tensile, Hardness, Impact)

- • Metallurgical testing

- • Ultrasonic testing

- • MPI testing

- • ISO 9001:2008